WHEN WILL I GET MY ITEMS DELIVERED?

Delivery : 2 – 7 Working Days

Subject to Stock Availability

Image(s) are only used for illustrative purposes and may not exactly depict the actual item.

Free delivery does not apply to large voluminous catering items or goods

International shipping fees are approximate and are subject to change after placing the order.

FREE DELIVERY : Orders Above R1000

Delivery Time: 2 – 7 Working Days

Subject to Stock Availability

Free delivery does not apply to large voluminous catering items or goods

International shipping fees are approximate and are subject to change after placing the order.

PAYFAST:

- Credit & Debit Payment

- Instant EFT

YOCO:

- Credit & Debit Payment

MANUAL EFT:

- Bank Transfer Through Online Banking

R7,780.00

Price Match Form

You can report the price details & where you have seen this product by filling the required information given in this form.

R

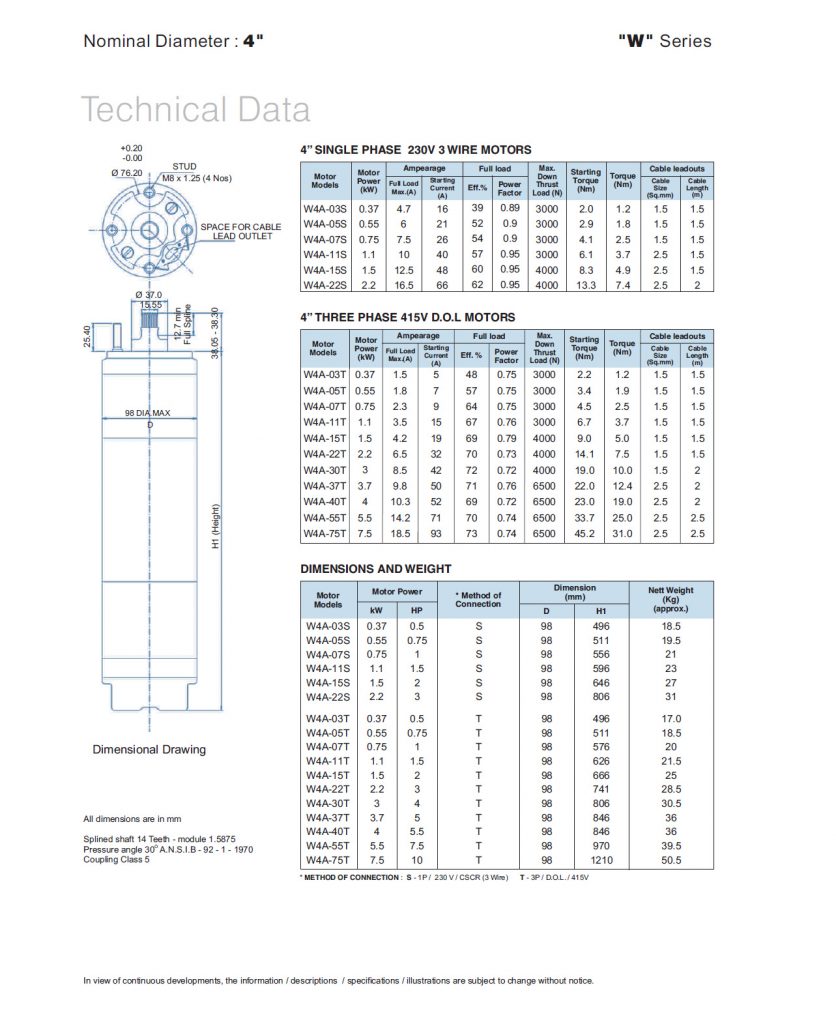

W Series Motor W4A-03T

These motors are eco-friendly wet type, water filled rewindable. The stator windings are of water proof synthetic film

insulated copper winding wires. It features water lubricated thrust and journal bearings. Motor is pre-filled with clear, cold, pure, fresh, filtered water.

However, on request motors can be pre-filled with water and propylene glycol (Anti-freeze agent) for places where the temperature is below the freezing conditions. Before commissioning, ensure the pre-filled level of water inside the motor. If any loss of volume is noticed, refill with clear, cold, pure, fresh, filtered water, through water filling plugs / valves provided in the upper housing.

Where the use of anti-freeze agent mixed water is not be allowed for special applications, these motors can also be filled with clear, cold, pure, fresh, filtered water and operated. Dynamically balanced rotors of these ‘W’ series motors maintain uniform clearance thereby giving better efficiency and increase the life cycle of the water lubricated bush bearings.

Specially designed high performance thrust bearings are used that can withstand high axial thrust loads and up thrust loads with minimum wear and tear. The unique design of thrust bearings creates a wedge of water between the shoe and the disc, and thereby providing better water lubrication and increases the life cycle of the thrust bearings.

Pressure equalizing rubber diaphragm is provided to guard the pressure and volume variations of the water inside the motor. Motor sealing are made by means of ‘O’ rings. Shaft seals and sand guard prevents ingress of well water. sand and fiber particles into the motor.

Care should be taken to ensure that the motor does not run when it is not submerged in the water, to prevent the

motor from dry running, install water level monitor/dry run preventor. The motor needs a constant flow of water past it’s body to keep it at correct operating temperature.

Ideally, the motor should be set just below the level at which water enters the bore well. When this level is not ascertained, fit a “ Flow inducer pipe” over the pumpset to ensure adequate cooling. It is mandatory to install a C.R.I. Control box for all single phase 3 wire motors. Mounting dimensions of motors are in accordance with NEMA standards.

| Brand | |

|---|---|

| Delivery Time |

You must be logged in to post a review.

W Series Motor W4A-03T

These motors are eco-friendly wet type, water filled rewindable. The stator windings are of water proof synthetic film

insulated copper winding wires. It features water lubricated thrust and journal bearings. Motor is pre-filled with clear, cold, pure, fresh, filtered water.

However, on request motors can be pre-filled with water and propylene glycol (Anti-freeze agent) for places where the temperature is below the freezing conditions. Before commissioning, ensure the pre-filled level of water inside the motor. If any loss of volume is noticed, refill with clear, cold, pure, fresh, filtered water, through water filling plugs / valves provided in the upper housing.

Where the use of anti-freeze agent mixed water is not be allowed for special applications, these motors can also be filled with clear, cold, pure, fresh, filtered water and operated. Dynamically balanced rotors of these ‘W’ series motors maintain uniform clearance thereby giving better efficiency and increase the life cycle of the water lubricated bush bearings.

Specially designed high performance thrust bearings are used that can withstand high axial thrust loads and up thrust loads with minimum wear and tear. The unique design of thrust bearings creates a wedge of water between the shoe and the disc, and thereby providing better water lubrication and increases the life cycle of the thrust bearings.

Pressure equalizing rubber diaphragm is provided to guard the pressure and volume variations of the water inside the motor. Motor sealing are made by means of ‘O’ rings. Shaft seals and sand guard prevents ingress of well water. sand and fiber particles into the motor.

Care should be taken to ensure that the motor does not run when it is not submerged in the water, to prevent the

motor from dry running, install water level monitor/dry run preventor. The motor needs a constant flow of water past it’s body to keep it at correct operating temperature.

Ideally, the motor should be set just below the level at which water enters the bore well. When this level is not ascertained, fit a “ Flow inducer pipe” over the pumpset to ensure adequate cooling. It is mandatory to install a C.R.I. Control box for all single phase 3 wire motors. Mounting dimensions of motors are in accordance with NEMA standards.

| Brand | |

|---|---|

| Delivery Time |

Reviews

There are no reviews yet.

You must be logged in to post a review.

Reviews

There are no reviews yet.